Streamlined Automation for Metal Bending

Meet Your New Robot Employee – Always on Duty, Always Precise

Welcome Innovation.

Say goodbye to downtime and inefficiencies.

With TeamRobotics® 24/7 Solution, you gain a tireless, precision-driven team member who never takes a break.

request a presentation

request a presentation

See our solution in action

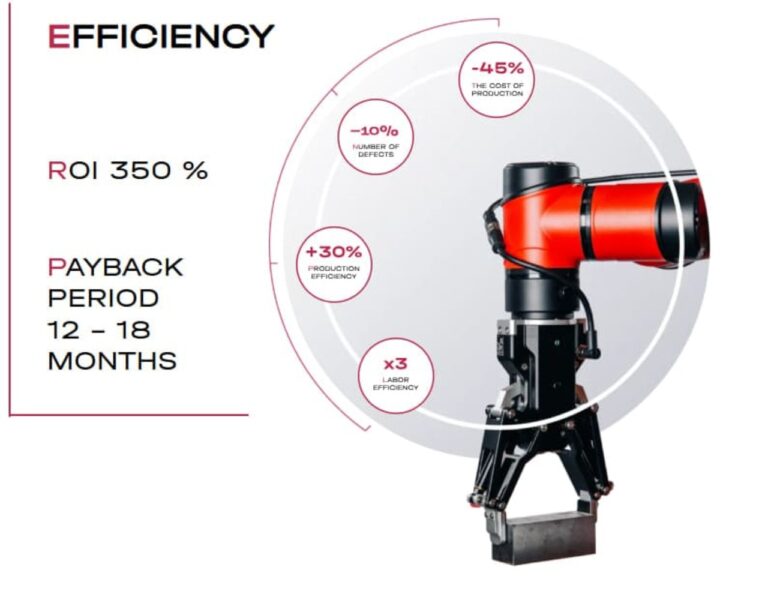

Why automate?

- Tackle workforce shortages

- Eliminate repetitive manual tasks

- Improve accuracy

- Reduce defects

- Triple your labor efficiency

- Enhance safety

- Recoup your investment in just 12 months while reducing operational costs

Why Choose TeamRobotics® Metal Bending Solutions?

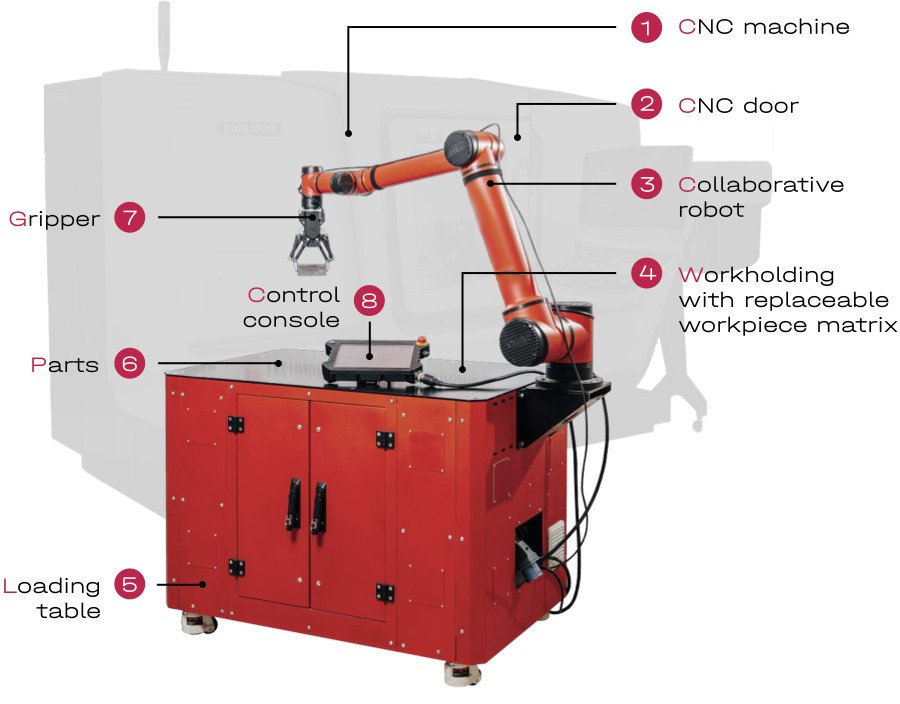

1. All-in-One System

- Integrated hardware and software, including collaborative robots, advanced PLCs, and cutting-edge technologies.

- Comprehensive service packages covering financial assessment and safety planning.

2. Ready-to-Use

- Fully automated in just a few days.

3. Seamless Integration

- Compatible with any brand of bending machines.

- Automates CNC machines—even those with 20+ years of service—in days.

4. Versatile Grippers

- Handles blanks up to 8 kg and sizes of 400 mm x 400 mm.

- Customizable for larger projects.

- Securely grips parts, ensuring stability during high-speed operations.

5. User-Friendly Operation

- Pre-loaded programs and intuitive controls for simple, stress-free use.

- Perfect for operators new to automation.

6. Quick Calibration

- Get production-ready in minutes—no extensive technical expertise required.

24/7 Precision and Productivity

Productivity Boost

Experience a significant enhancement in operational efficiency 24/7.

Lower Costs, Higher Returns

Reduce operational costs with our optimized resource management.

Real-Time Insights

Track performance and productivity with live data monitoring

Adaptive Design

Our design adapts seamlessly to any project needs for greater versatility.

How It Works

Our robot employee is not just advanced—it’s approachable, making complex operations feel effortless.

1. Setup – Begin with an intuitive configuration process. – Customize gripper options, workflows, and parameters with ease.

2. Simulation – Visualize your ideas in a digital simulation. – Optimize every motion for accuracy before going live.

3. Execution – Sit back as your robotic colleague manages all bending operations. – Enjoy precision, speed, and reliability.

4. Monitoring – Use real-time diagnostics and error detection tools. – Ensure smooth performance with seamless troubleshooting.

1. Setup – Begin with an intuitive configuration process. – Customize gripper options, workflows, and parameters with ease.

2. Simulation – Visualize your ideas in a digital simulation. – Optimize every motion for accuracy before going live.

3. Execution – Sit back as your robotic colleague manages all bending operations. – Enjoy precision, speed, and reliability.

4. Monitoring – Use real-time diagnostics and error detection tools. – Ensure smooth performance with seamless troubleshooting.

Developed in Partnership with Micro Metal Ltd.Works

Built with Expertise, Trusted by Professionals

Developed in collaboration with Micro Metal Works, this solution sets a new standard in practicality. Together, we’ve created a system that is not only easy to deploy but robust enough to meet the most demanding industry needs.

https://youtu.be/JLn4RstByrI 5/5“TechnoRobotics’ solutions for robot-based collaborative automation were designed with our needs in mind. This is why I signed a business cooperation agreement with them. We successfully started a pilot application in bending automation in the factory… In our estimation, within about five years, up to half of the machines can be converted by TechnoRobotics to automation.”

Eyal Ezer

Founder, Micro Metal Works LTD