Aiming to boost productivity, remove operational glitches, and upscale operations while maintaining costs?

Grappling with labor shortages and safety issues, or endeavoring to cut high labor? If this resonates with you, consider ‘All in One’ cobotic solutions.

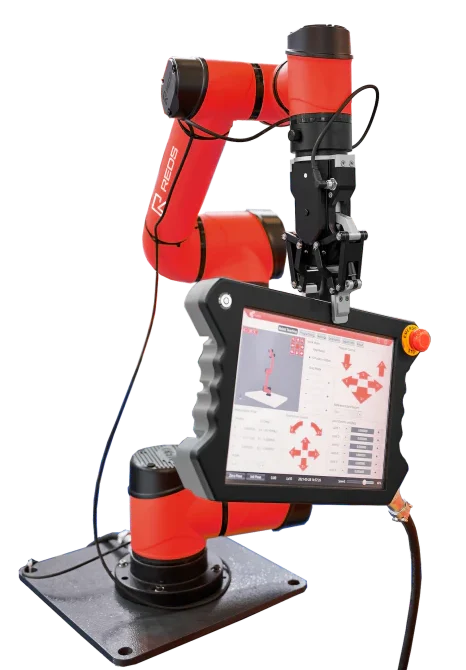

In addition to ready-to-install, easy-to-retrofit, and versatile robotic products, TeamRobotics® solutions include installation, safety planning, education and training, technical support, monitoring, and outcomes evaluation.

Watch and analyze how collaborative robots, also known as cobots, work in real-world, unadorned manufacturing environments.

As one of its many applications, TeamRobotics® ‘Smart ‘All-in-One’ Solution for Palletizing can operate up to four conveyors concurrently, accommodate existing setups, and significantly cut labor costs. It abolishes hazardous jobs, enforces stringent occupational safety standards – including daily weight limits – and guarantees steady productivity levels

4 workers / 1 line = 4 operations

1 operator/1 cobot/ 1 line = 4 operations

1 operator/2 cobots/ 4 lines=16 operations

TeamRobotics® solutions will help you to enhance occupational health and safety, to eliminate repetitive manual processes, to cut potentially dangerous jobs, and to downsize the rate of related accidents.

The environmental footprints decrease through reduction in excess processing and defects, better waste management, and energy efficiency improvement.

Cut potentially dangerous jobs, downsize the rate of related accidents.

Decrease person-to-person transmission, stay safe regardless of pandemics.

Eliminate human errors.

Ensure consistency and accuracy.

Decrease waste and defective parts.

Increase significantly the number of machines per operator.

Put upskilled workers at the center of manufacturing process while eliminating cut time-consuming, repetitive manual processes.

Configure a safety plan.

Install plug-and-play software and other components.

Educate and train your staff.

Integrate TeamRobotics® solution to your manufacturing.

Elevate your business with the skills needed to deploy, program, and set your cobot up for optimal performance.

Online or in-house, training programs that can take your knowledge from beginner to confident robot technician.

Leave your contacts and you will receive an efficiency calculation shortly, but sometimes it can take up to 12 hours.

No. We have simplified the integration process as much as possible and reduced the costs of implementing the robot.

Our robots are designed are specially designed to control industrial machines and supplied with software and the necessary equipment to perform typical tasks for automating machines. This allows us to launch the robot in a few hours, and not in weeks or months, in comparison with other solutions. It also allows you to quickly reconfigure the robot in a matter of minutes.

While other solutions are still at the design stage, Reload works and helps to fulfill the tasks of your business.

Yes. Please feel free to contact us for further information.

Our robots team up with you

to raise safety, quality

and efficiency

call us to envision how robots will enable your business to succeed, grow and flourish

Do you have any questions?

Contact us, and we will provide to you all the information.

Work:

Founder&CEO, Technored – robotics

CEO, KAMI Group – industrial machinery and automation.

Educational:

– MS in Automation of technological and manufacturing processes from Moscow State Industrial University

– Stanford University – Leadership and Design Thinking Program

Work:

Chief Strategy Officer,

Deputy CEO of Rosatom Trading & Mining Divisions.

Chief Non-Financial Risk Officer,

Non-Financial Risk Manager,

Sustainability Reporting Program Director

Executive Director,

Institute for Urban Economics.

Educational:

– MS in Industrial Automation and PhD in Economics from State University of Management, Russia.

– Graduate Center, CUNY – Fellowship, Senior Fellowship.

Nous serons heureux de vous fournir des supports de présentation ou d’organiser une présentation sur site dans votre entreprise.

Laissez une demande, et nous vous contacterons dans les 24 heures.

Avez-vous des questions ?

Contactez-nous, et nous vous fournirons toutes les informations nécessaires.

Chętnie dostarczymy materiały prezentacyjne lub przeprowadzimy prezentację w siedzibie Państwa firmy.

Zostaw zgłoszenie, a skontaktujemy się z Państwem w ciągu 24 godzin.

Wir stellen Ihnen gerne Präsentationsmaterial zur Verfügung oder führen eine Vor-Ort-Präsentation in Ihrem Unternehmen durch.

Hinterlassen Sie eine Anfrage, und wir werden uns innerhalb von 24 Stunden bei Ihnen melden.

Haben Sie Fragen?

Kontaktieren Sie uns, und wir werden Ihnen alle Informationen zur Verfügung stellen.

Leave your contacts and you will receive an efficiency calculation shortly, but sometimes it can take up to 12 hours.